Schaeffler - a supplier of products and services for automotive and industrial vehicles, is expanding its range of solutions for the electrification of commercial vehicle powertrains. This is a key contribution to sustainable development and climate change, which will help companies meet tighter limits on CO2 emissions and environmental pollution. “The vehicle sector is facing significant challenges,” says Matthias Zink, General Manager Automotive Mechanics at Schaeffler AG. “We use our extensive systems knowledge and experience in vehicles to shape the world's new transportation system. We have recently awarded two major contracts, confirming that we are becoming the technology partner of choice in the commercial vehicle sector.”

Contracts for electric motors and hybrid drives

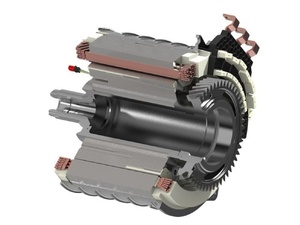

Schaeffler has won a contract for the mass production of electric motors for one of the largest subcontractors in the commercial vehicle sector. Production will start in 2023. The 800V motor installed in fuel cell vehicles provides a maximum continuous power of 180kW and a drive torque of 950Nm. In addition, it adopts an innovative wave winding technology for high power density and easy assembly. The engine plays an important role in the electrification of commercial vehicles and contributes to a significant reduction in CO2 emissions. In addition, Schaeffler has been awarded a contract for the mass production of hybrid drives. These drives are based on the extremely efficient P1 architecture and provide brake energy recovery. The recovered energy is used to power the on-board systems, in particular the new exhaust aftertreatment system, ensuring that the vehicle meets NOx and CO2 emissions requirements. The start of production is scheduled for 2024.

Dr. Jochen Schröder, Head of Schaeffler's Electric Vehicle Business Unit, comments: “We are very efficient in our electric transport business. Schaeffler offers a wide range of powertrain electrification solutions, including 48V hybrid drives, plug-in hybrid technology and all-electric motors. We can provide a full cycle of development and production of components and systems in-house, providing an ideal environment for cooperation with customers in a variety of markets related to transportation.”

Schaeffler promotes responsible action in business

The Schaeffler Group assumes environmental and social responsibility for successful sustainability. In addition, sustainability has a significant impact on the development of the corporate strategy of Schaeffler, the world's leading supplier of products and services for the automotive and industrial sectors. Therefore, it is on the list of the main elements of the "Roadmap-2025", which will ensure the implementation of new opportunities by the company.

The engine provides a maximum continuous power of 180 kW and a maximum drive torque of 950 Nm.